Factors affecting basic iron consumption

To analyze a problem, we first need to know some basic theories, which will help us understand. Firstly, we need to know two concepts. One is alternating magnetization, which, to put it simply, occurs in the iron core of a transformer and in the stator or rotor teeth of a motor; One is the rotational magnetization property, which is produced by the stator or rotor yoke of the motor. There are many articles that start from two points and calculate the iron loss of the motor based on different characteristics according to the above solution method. Experiments have shown that silicon steel sheets exhibit the following phenomena under magnetization of two properties:

When the magnetic flux density is below 1.7 Tesla, the hysteresis loss caused by rotating magnetization is greater than that caused by alternating magnetization; When it is higher than 1.7 Tesla, the opposite is true. The magnetic flux density of the motor yoke is generally between 1.0 and 1.5 Tesla, and the corresponding rotational magnetization hysteresis loss is about 45 to 65% greater than the alternating magnetization hysteresis loss.

Of course, the above conclusions are also used, and I have not personally verified them in practice. In addition, when the magnetic field in the iron core changes, a current is induced in it, called eddy current, and the losses caused by it are called eddy current losses. In order to reduce eddy current loss, the motor iron core usually cannot be made into a whole block, and is stacked axially by insulated steel sheets to hinder the flow of eddy currents. The specific calculation formula for iron consumption will not be cumbersome here. The basic formula and significance of Baidu iron consumption calculation will be very clear. The following is an analysis of several key factors that affect our iron consumption, so that everyone can also forward or backward deduce the problem in practical engineering applications.

After discussing the above, why does the manufacturing of stamping affect iron consumption? The characteristics of punching process mainly depend on different shapes of punching machines, and determine the corresponding shear mode and stress level according to the needs of different types of holes and grooves, thereby ensuring the conditions of shallow stress areas around the periphery of the lamination. Due to the relationship between depth and shape, it is often affected by sharp angles, to the extent that high stress levels can cause significant iron loss in shallow stress areas, especially in the relatively long shear edges within the lamination range. Specifically, it mainly occurs in the alveolar region, which often becomes a focus of research in the actual research process. Low loss silicon steel sheets are often determined by larger grain sizes. Impact can cause synthetic burrs and tearing shear at the bottom edge of the sheet, and the angle of impact can have a significant impact on the size of burrs and deformation areas. If a high stress zone extends along the edge deformation zone to the interior of the material, the grain structure in these areas will inevitably undergo corresponding changes, be twisted or fractured, and extreme elongation of the boundary will occur along the tearing direction. At this time, the grain boundary density in the stress zone in the shear direction will inevitably increase, leading to a corresponding increase in iron loss within the region. So, at this point, the material in the stress area can be regarded as a high loss material that falls on top of the ordinary lamination along the impact edge. In this way, the actual constant of the edge material can be determined, and the actual loss of the impact edge can be further determined using the iron loss model.

1.The Influence of Annealing Process on Iron Loss

The influence conditions of iron loss mainly exist in the aspect of silicon steel sheets, and mechanical and thermal stresses will affect silicon steel sheets with changes in their actual characteristics. Additional mechanical stress will lead to changes in iron loss. At the same time, the continuous increase in internal temperature of the motor will also promote the occurrence of iron loss problems. Taking effective annealing measures to remove additional mechanical stress will have a beneficial effect on reducing the iron loss inside the motor.

2.Reasons for excessive losses in manufacturing processes

Silicon steel sheets, as the main magnetic material for motors, have a significant impact on the performance of the motor due to their compliance with the design requirements. Additionally, the performance of silicon steel sheets of the same grade may vary from different manufacturers. When selecting materials, efforts should be made to select materials from good silicon steel manufacturers. Below are some key factors that have actually affected iron consumption that have been encountered before.

The silicon steel sheet has not been insulated or properly treated. This type of problem can be detected during the testing process of silicon steel sheets, but not all motor manufacturers have this testing item, and this problem is often not well recognized by motor manufacturers.

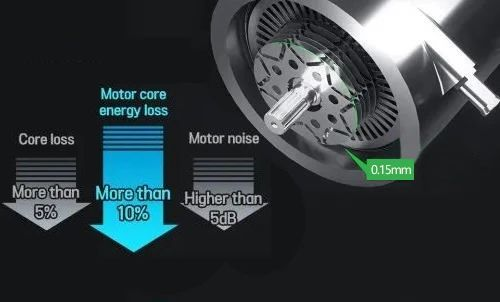

Damaged insulation between sheets or short circuits between sheets. This type of problem occurs during the manufacturing process of the iron core. If the pressure during the lamination of the iron core is too high, causing damage to the insulation between the sheets; Or if the burrs are too large after punching, they can be removed by polishing, resulting in serious damage to the insulation of the punching surface; After the iron core lamination is completed, the groove is not smooth, and the filing method is used; Alternatively, due to factors such as uneven stator bore and non concentricity between the stator bore and the machine seat lip, turning may be used for correction. The conventional usage of these motor production and processing processes actually has a significant impact on the performance of the motor, especially the iron loss.

When using methods such as burning or heating with electricity to disassemble the winding, it can cause the iron core to overheat, resulting in a decrease in magnetic conductivity and damage to the insulation between the sheets. This problem mainly occurs during the repair of winding and motor during the production and processing process.

Stacking welding and other processes can also cause damage to the insulation between the stacks, increasing eddy current losses.

Insufficient iron weight and incomplete compaction between sheets. The ultimate result is that the weight of the iron core is insufficient, and the most direct result is that the current exceeds the tolerance, while there may be the fact that the iron loss exceeds the standard.

The coating on the silicon steel sheet is too thick, causing the magnetic circuit to become too saturated. At this time, the relationship curve between no-load current and voltage is severely bent. This is also a key element in the production and processing process of silicon steel sheets.

During the production and processing of iron cores, the grain orientation of the silicon steel sheet punching and shearing surface attachment may be damaged, leading to an increase in iron loss under the same magnetic induction; For variable frequency motors, additional iron losses caused by harmonics should also be considered; This is a factor that should be comprehensively considered in the design process.

In addition to the above factors, the design value of motor iron loss should be based on the actual production and processing of the iron core, and every effort should be made to ensure that the theoretical value matches the actual value. The characteristic curves provided by general material suppliers are measured using the Epstein square coil method, but the magnetization direction of different parts in the motor is different, and this special rotating iron loss cannot be considered at present. This can lead to varying degrees of inconsistency between calculated and measured values.

Methods for reducing iron loss in engineering design

There are many ways to reduce iron consumption in engineering, and the most important thing is to tailor the medicine to the situation. Of course, it’s not just about iron consumption, but also about other losses. The most fundamental way is to know the reasons for high iron loss, such as high magnetic density, high frequency, or excessive local saturation. Of course, in the normal way, on the one hand, it is necessary to approach reality as close as possible from the simulation side, and on the other hand, the process is combined with technology to reduce additional iron consumption. The most commonly used method is to increase the use of good silicon steel sheets, and regardless of cost, imported super silicon steel can be chosen. Of course, the development of domestic new energy driven technologies has also driven better development in the upstream and downstream. Domestic steel mills are also launching specialized silicon steel products. Genealogy has a good classification of products for different application scenarios. Here are a few straightforward methods to encounter:

1. Optimize magnetic circuit

Optimizing the magnetic circuit, to be precise, is optimizing the sine of the magnetic field. This is crucial, not only for fixed frequency induction motors. Variable frequency induction motors and synchronous motors are crucial. When I was working in the textile machinery industry, I made two motors with different performance to reduce costs. Of course, the most important thing was the presence or absence of skewed poles, which resulted in inconsistent sinusoidal characteristics of the air gap magnetic field. Due to working at high speeds, the iron loss accounts for a large proportion, resulting in a significant difference in the losses between the two motors. Finally, after some backward calculations, the iron loss difference of the motor under the control algorithm has increased by more than twice. This also reminds everyone to coupling control algorithms when making variable frequency speed control motors again.

2.Reduce magnetic density

Increasing the length of the iron core or increasing the magnetic conductivity area of the magnetic circuit to reduce magnetic flux density, but the amount of iron used in the motor increases accordingly;

3.Reducing the thickness of iron chips to reduce the loss of induced current

Replacing hot-rolled silicon steel sheets with cold-rolled silicon steel sheets can reduce the thickness of silicon steel sheets, but thin iron chips will increase the number of iron chips and motor manufacturing costs;

4.Adopting cold rolled silicon steel sheets with good magnetic conductivity to reduce hysteresis loss;

5.Adopting high-performance iron chip insulation coating;

6.Heat treatment and manufacturing technology

The residual stress after processing iron chips can seriously affect the loss of the motor. When processing silicon steel sheets, the cutting direction and punching shear stress have a significant impact on the loss of the iron core. Cutting along the rolling direction of the silicon steel sheet and conducting heat treatment on the silicon steel sheet can reduce losses by 10% to 20%.

Post time: Nov-01-2023